Servos Vs. Pneumatics

Pneumatic systems use electricity to compress air into energy, while Servo systems use electric motors for precise control. Although both motors allow for mechanical movement, pneumatic systems in relation are inefficient and lose approximately 90% of energy upon output, resulting in a 10% efficiency rate while being a less precise type of control. Servo motors however, maintain a minimum of 85% efficiency rate for energy output while providing fast accurate responses.

During the purchasing process of each machine, the initial costs of pneumatic systems tend to be on the lower end while servo systems have a higher upfront cost. However, the long-term operating costs of each system is one of the main differentiating factors.

- Pneumatic systems require regular maintenance due to leaks or seals that wear out over time, leading to a regular, costly replacement schedule. Due to the high amounts of energy needed to compress air, 75% of annual operating costs is also contributed to the electricity needed to run this system.

- Servo systems have a high initial cost but maintains low operating costs. With a more predictable life span and low maintenance, servo systems also offer superior performance at higher speeds with precise control.

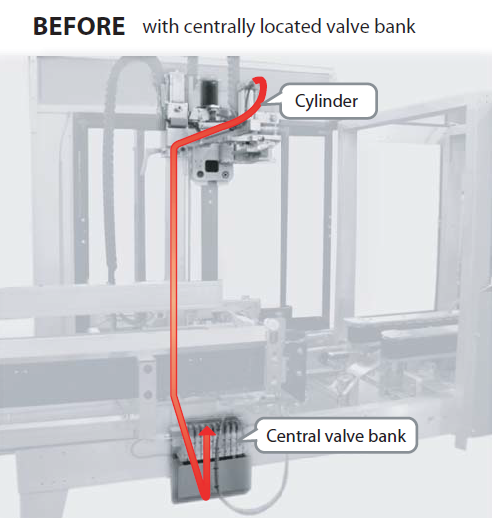

OnSite Valve Technology

On Wexxar Bel machines, moving from pneumatic to servo results in 40% of SCFM savings. For machines that only offer pneumatic systems, Wexxar Bel utilizes OnSite Valve Technology to optimize possible energy savings.